Product Specs

Ratings

- Power Range

- 641 BHP

Dimensions & Weights

- Engine Dry Weight - Approximate

- 2295 lb

- Height

- 38.7 in

- Length - Engine

- 47.9 in

- Width - Engine

- 38.7 in

Engine Specifications

- Aspiration

- TSA

- Bore

- 4.6 in

- Configuration

- In-line 6, 4-Stroke-Cycle Diesel

- Displacement

- 531 in³

- Emissions

- EPA Tier 3 Recreational & Commercial, IMO II, EU Stage IIIA (EU IW)

- Rotation from Flywheel End

- Counterclockwise

- Speed Range

- 2300 rpm

- Stroke

- 5.3 in

Standard Equipment

-

- Air Inlet System

-

- Supercharger, electronically controlled belt driven

- Air cleaner/fumes disposal (closed system)

- Turbochargers, jacket water cooled

- Aftercooler condensate drain

-

- Control System

-

- Cold mode start strategy

- PWM secondary throttle

- Cold mode start strategy

- Electronic diagnostics and fault logging

- Engine and transmission monitoring (temperature, pressure)

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions

- Three types of throttle inputs (CAN, PWM, and 0-5V)

- 70-pin customer connector

-

- Cooling System

-

- Sea water pump, bronze impeller, gear driven, for HEX cooled engines only

- Sea water aftercooled

- Jacket water pump, belt driven

- JW Heat Exchanger - Corrosion resistant shell and tube style

- Fuel cooler

- Expansion tank

- Thermostat housing (fully open temp 95 C)

- 63mm hose bead raw water inlet

- 50 mm hose bead raw water oulet

-

- Exhaust System

-

- Water-cooled exhaust manifold & turbocharger

- 90mm ID round flanged exhaust outlet

-

- Flywheels & Flywheel Housings

-

- Flywheel Housing, SAE No. 1 - With M10 Threads

- Flywheel, SAE 14, 149 teeth - With M12 Threads

- SAE standard rotation

-

- Fuel System

-

- High Pressure Common Rail fuel system

- High pressure fuel system pump with integral low pressure fuel transfer pump

- Primary fuel filter, remote mounted with integrated electric priming pump

- Secondary fuel filter, Rear mounted for LH and RH Service

-

- Lube System

-

- Crankcase breather, closed crankcase ventilation

- Oil filter, cartridge style, Rear mounted for LH and RH service

- Oil cooler

- Oil pan, center sump

- Oil pump, gear driven

- Dipstick, RH service on Port, LH service on Starboard

-

- Mounting System

-

- Front and rear support brackets

-

- General

-

- Front belt and damper guard

- Lifting eyes

- RH or LH service options

- Upper front-facing customer wiring connector and Service Tool connection

-

- Protection System

-

- Electronic Engine Monitoring System provides engine de-rate strategies to protect against adverse operating conditions

-

- Paints

-

- Engines are painted Matterhorn white with pleasure craft finish includes epoxy primer with polyurethane topcoat. Fuel lines, water lines and clamps and wiring harness will be unpainted. Standard decals and informational films will be installed. Shipped loose parts will be shipped as received from suppliers. Heat sensitive components have a textured black finish.

Attachments

-

- Control System

-

- Instrument Panels

-

- Instrumentation

-

- Transmission Sensors

-

- Mounting System

-

- Vibration isolation mounting

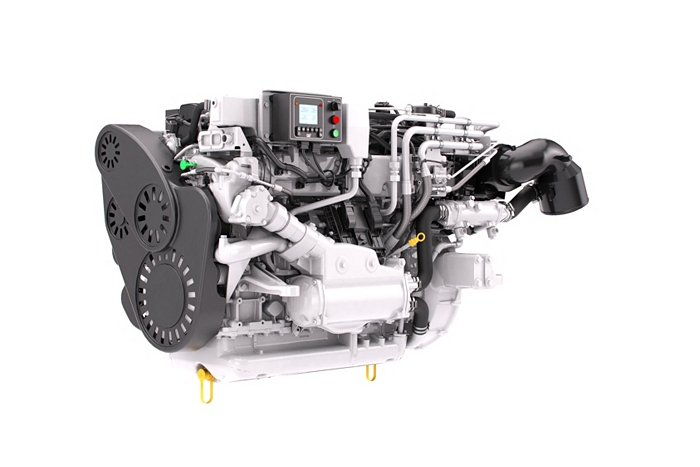

Exterior View

Exterior View